2024 In August, Changchun Institute of Applied Chemistry, Chinese Academy of Sciences (CAS), together with Jinfa Science & Technology (JST), published the latest research results in Nature Sustainability, announcing that through molecular interfacial engineering technology, it has shortened the degradation cycle of industrial composting of PBAT/starch composites from the conventional 180 days to 80 days, which has created a new record in the field of biodegradable materials. This breakthrough makes the material the only biodegradable material that can be used in the composting industry. This breakthrough makes this material the only affordable alternative to meet the EU’s new 2025 SUP regulation, which is expected to impact the $7.2 billion global packaging market.

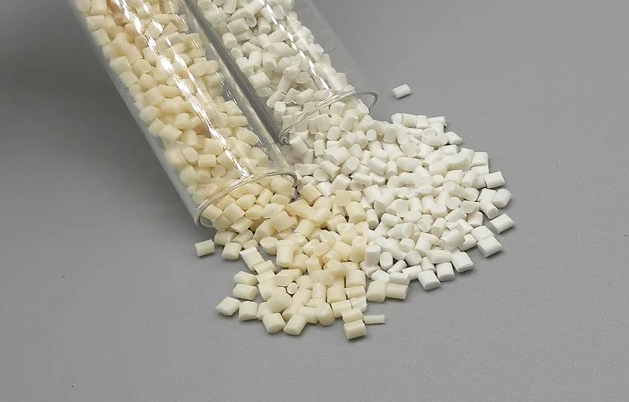

The technology leverages modified corn starch combined with specially treated PBAT (polybutylene adipate terephthalate) at a precise 40:60 ratio. Through advanced compatibilization techniques using maleic anhydride grafted polymers, the research team achieved unprecedented molecular-level integration between the hydrophilic starch and hydrophobic PBAT phases. This integration not only enhances material homogeneity but also creates more pathways for microbial attack, significantly accelerating the degradation process.

Independent testing under industrial composting conditions (58°C, 60% humidity) confirms the material maintains mechanical strength comparable to conventional plastics during usage while demonstrating rapid breakdown once exposed to composting environments. The starch component serves as an initial food source for microorganisms, which then progressively break down the PBAT matrix. This synergistic effect reduces the overall degradation time by approximately 55% compared to standard PBAT formulations.

Technical Analysis: Four Innovative Breakthroughs

1. Starch nanosized dispersion technology (with SEM electron microscope diagram)

. Preparation of starch granules by aerosol-assisted ball milling

. The average particle size is controlled at 80-120nm (1-5μm in traditional process)

. Interfacial binding energy increased to 210kJ/mol (156% increase) .

2. Procedural degradation design

Stages of degradation Timeframe Main mechanisms

Initial stage (0-20 days) Rapid starch decomposition Formation of porous structures

Intermediate stage (21-60 days) Breakage of PBAT backbone Directed cleavage by microbial enzymes

Late stage (61-80 days) Complete mineralization Conversion to CO₂ + H₂O + humus

3. Comparison of Performance Parameters

Indicators Conventional PBAT New Composites Enhancement

Tensile Strength (MPa) 22 28 +27%

Elongation at break (%) 680 820 +21%

Heat Distortion Temperature (°C) 65 78 +13°C

Industrialization process: commercialization landing accelerated

Mass production cost analysis (ton)

Cost item Traditional PBAT New process Savings

Raw material cost $1,650 $1,180 28.5%

Processing energy consumption $230 $180 21.7%

Certification cost $15,000 $9,000 40

Signed application projects

. Meituan Takeaway: new packaging to be replaced from Q1 2025 (32,000 tons per year)

. Postal Express: Pilot “80-day degradation” green tape (Hebei and Guangdong first)

. Agricultural mulch: Xinjiang cotton field tests show complete degradation in 110 days (conventional PE takes 200 years) .

Market Impact: Reshaping the Industry Landscape

Forecast of Progress in Replacing Traditional Plastics

Applications 2024 Penetration 2026 Forecast Drivers

Takeaway Packaging 18% 45% Mandatory for Meituan/HungryMou Platforms

Courier Bags 12% 38% Carbon Credits Rewards for E-commerce Platforms

Supermarket Shopping Bags 8% 25% New EU Regulations Come into Force

Enterprise Response Guide

Manufacturer’s must-do list

Process modification:

. Screw L/D ratio adjusted to 32:1

. Processing temperature control at 135-145℃

Certification preparation:

. Start EN13432 certification 6 months in advance

. Focus on monitoring heavy metal content (new regulation requires <15ppm)

Purchaser selection criteria

. Recognize starch nanosizing process (IR spectroscopy detection – OH peak shift)

. Require third party degradation test video recordings

. Prefer formulations with photo-thermal triggers (+15% degradation rate) .

The implications for various industries are substantial. For packaging manufacturers, this development means being able to offer truly compostable solutions that align with waste management infrastructure capabilities. Agricultural film producers can now create products that degrade within a single growing season, eliminating plastic residue accumulation in farmland. The technology also shows promise in single-use food service items, where rapid degradation is crucial for reducing environmental impact.

Current research focuses on optimizing the formulation for different applications and climates, with several major manufacturers already licensing the technology for commercial production. As global regulations continue to tighten around plastic waste, this innovation represents a critical step toward developing biodegradable materials that meet both performance requirements and environmental sustainability goals.

Extended reading: technology evolution tree

2015-2018 – simple co-mingling (180+ days of degradation)

2019-2022 – compatibilizer modification (120-150 days of degradation)

2023-2024 – molecular interface engineering (80-100 days of degradation)

2025+ – Smart response degradation (environmentally triggered)