In the supermarket, an aunt is using our biodegradable vegetable bags. She picked up a bag and studied it carefully. She found that the logo of “industrial compost” and the words of EN13432 certification were printed on it. She compared the traditional plastic bags in her hand. “I heard that this is made of PLA/PBAT raw materials?”

Such scenes are being staged all over the country. With the implementation of the new EN13432-2024 standard, biodegradable bag manufacturers like us who adopt PLA+PBAT+Corn Strach are facing unprecedented opportunities and challenges. According to statistics, after the implementation of the new standard, the pass rate of the first batch of products for inspection is less than 60%, which reflects the profound changes in raw material formula, production technology and certification standards of the whole industry.

Certification upgrade: a rigorous test from laboratory to market

Our products have obtained many certifications, such as BPI, OK COMPOST INDUSTRIAL, EN13424, etc. Behind each certificate is a series of rigorous test data. Taking the new EN13432 standard as an example, the assessment period of biodegradation rate has been extended from 90 days to 180 days, and the heavy metal content standard has been improved by 2.5 times. This means that the purity of our PLA raw material must reach above 99.9%, and the catalyst residue should be controlled at ppm level during PBAT synthesis.

In the actual test, our products are under the industrial composting environment of 58℃:

1,Disintegration began to appear on the 45th day.

2,The biodegradation rate reached 88% on the 120th day.

3,The final degradation rate exceeded 92% on the 180th day.

These data seem simple, but in fact they need the precise coordination of raw material ratio, processing technology and subsequent treatment.

Scientific code of raw material formula

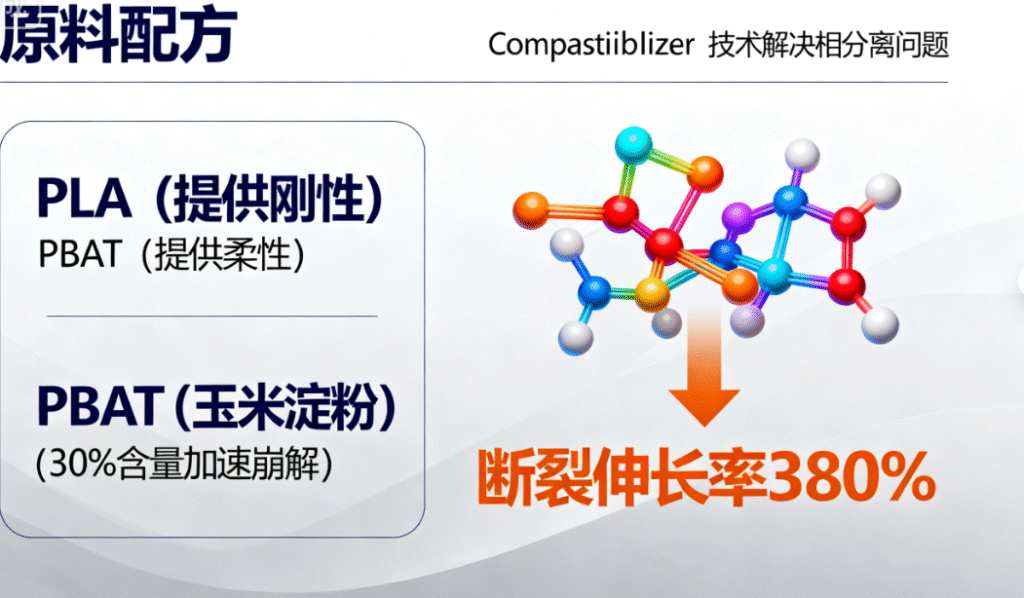

We adopted the ternary system of PLA+PBAT+ corn starch, and after 18 months of research and development, we finally found the best ratio. Among them:

PLA (Polylactic acid) provides rigidity, which comes from corn starch fermentation.

PBAT (Polyadipate/Butylene Terephthalate) gives flexibility.

30% corn starch content accelerates initial disintegration.

In addition, we successfully solved the problem of phase separation between PLA and PBAT through the patented compatibilizer technology, which increased the elongation at break of the material to 380%, fully meeting the requirements of shopping bags. At the same time, the addition of corn starch not only reduces the cost, but more importantly, its hydrophilicity significantly improves the biodegradation rate of the material.

Difficult realistic environment

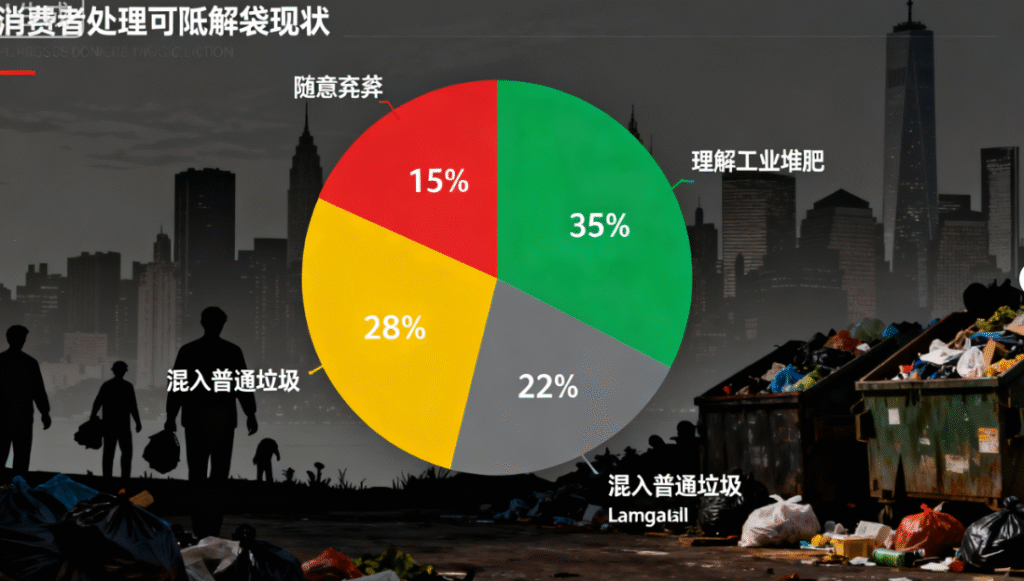

However, the ideal conditions of the laboratory are often difficult to replicate in reality. A survey in 2023 showed that among consumers who advertised to use biodegradable bags:

Only 35% people understand the concept of industrial composting.

28% of the bags were mistakenly put into ordinary garbage bags.

22% of the bags end up in landfills.

15% bags are scattered in the natural environment.

What is even more worrying is that it takes 2-3 years for a biodegradable bag to completely decompose at room temperature, and tens of thousands of microplastics particles will be produced in this process. Our field monitoring data show that in the same time, traditional plastic bags remain intact, while biodegradable bags will break into 0.5-2mm particles.

Case enlightenment

The case of the German town of Schweiqingen is thought-provoking. This small town with a population of only 30,000 has carried out a comprehensive effect evaluation after implementing biodegradable bags for two years. The results show that:

The proportion of pollutants in composting facilities is as high as 12%

Sorting costs increased by 45%

Due to mixed release, 3 tons of compost raw materials had to be discarded.

“We realize that it is not enough to promote biodegradable bags alone,” lamented the head of the local environmental department. “A complete recycling system must be established.”

Professional advice to consumers

Look for the certification mark

EN13432: Industrial Compost Certification

OK COMPOST HOME: home composting certification

BPI: Certified by American Biodegradable Products Association

Master the essentials of use

It is suggested that the number of reuse times should not be less than 10 times.

Bearing capacity shall not exceed 5kg.

Avoid prolonged exposure to sunlight.

Correct handling method

Confirm whether there are industrial composting facilities in the local area

According to the identification, correctly classify and release.

Bags with serious pollution should be treated as other garbage.

Towards a sustainable future

The fourth generation biodegradable materials we are developing have shown encouraging prospects. The latest experimental data show that the degradation rate of new materials can reach 80% within 6 months in natural environment, and almost no microplastics is produced. At the same time, the closed-loop system of “bag recycling-composting-agricultural application” established in cooperation with several cities has also achieved initial results.

In this system, the used biodegradable bags are collected and converted into organic fertilizers in composting facilities, and these fertilizers are used in the surrounding ecological farms.

As an environmental expert said, “The real sustainability lies not in the material itself, but in how we use and deal with it.” Every environmental protection choice deserves respect, but it needs scientific cognition and system support.

(The data in this paper comes from laboratory test records, market research reports and monitoring data of international cooperation projects.)