In the supermarket, my aunt looks at the biodegradable shopping bag she just bought. “Is this bag made of corn?” She pointed to the OK COMPOST certification mark on the bag and asked the staff, “What should I do after using it?”

This question just reveals the most critical link in the whole life cycle of biodegradable bags from production to disposal. As a biodegradable bag manufacturer that has passed many international certifications such as EN13432 and BPI, we hope to show you the scientific story behind this “green mile”.

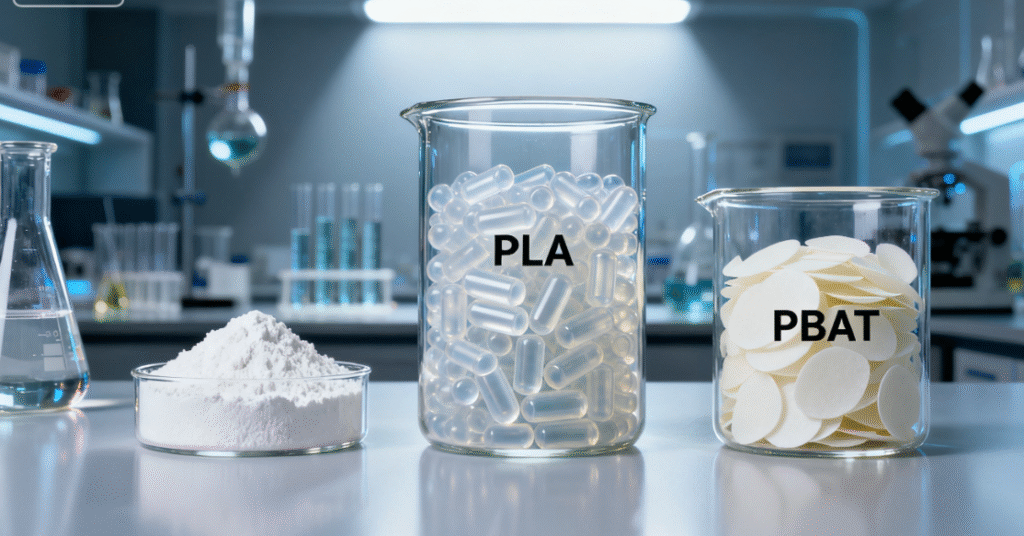

Exploration of raw materials: the perfect integration of nature and technology

Our biodegradable bag consists of three raw materials: PLA, PBAT and corn starch. These raw materials contain precise scientific proportions:

PLA comes from the deep processing of corn starch. Through fermentation, purification and other processes, the sugar in corn is converted into lactic acid, and then polymerized into high-performance polylactic acid. In addition, we choose non-edible aged corn, which will not affect food security. For every ton of PLA produced, it needs to consume 2.5 tons of corn. With the continuous optimization of our technical team, the conversion rate has increased by 15% compared with the industry average.

As a biodegradable material, PBAT gives the bag good flexibility and tensile strength. Through the optimization of molecular structure, it can be quickly identified and decomposed by microorganisms in composting environment. In addition, the PBAT raw materials we used have passed the REACH certification of the European Union, and are completely free of harmful substances such as heavy metals.

The addition of corn starch is strictly controlled at about 30%, which can not only ensure the initial disintegration of the material, but also will not affect the mechanical strength of the bag. Through the unique compatilizer technology, we successfully solved the interface compatibility problem of starch with PLA and PBAT. In the actual test, the bag with this ratio can be reused for more than 15 times under the condition of bearing 5 kg, which fully meets the daily shopping needs.

The severe test of certification

Obtaining EN13432, BPI, OK COMPOST and other certifications means that the product must pass a series of rigorous tests:

In the biodegradability test, the sample should reach more than 90% degradation rate within 180 days under the composting environment of 58 2℃. Our measured data showed that the product began to disintegrate on the 45th day, the degradation rate reached 85% on the 20th day, and finally the degradation rate reached 93.5% on the 175th day. This data is far higher than the requirements of certification standards, which proves the excellent biodegradability of our formula.

The ecotoxicity test is equally strict. We used the degraded products in plant planting experiments, and required that the germination rate and biomass should not be lower than that of the control group. This means that not only must the bag be completely decomposed, but its decomposition products must also be harmless to the environment. In our test, the germination rate of rapeseed planted with degradation products reached 96%, which was 3 percentage points higher than that of the control group using ordinary soil.

Realistic challenge: the gap between ideal and reality

Despite its excellent performance in the laboratory, biodegradable bags still face many challenges in the promotion process:

The first is the supporting problem of the recycling system. According to our market research data in 2023, at present, less than 30% cities in China have established perfect industrial composting facilities, which leads to many bags that should have entered the composting system being wrongly disposed. In the 25 key cities that participated in the survey, only 12% biodegradable bags in each city were sent to composting facilities correctly.

Secondly, consumers’ cognitive misunderstanding. Our market survey shows that more than 60% consumers think that biodegradable bags can be discarded in the natural environment at will, which will actually cause new environmental problems. What is even more worrying is that 45% of consumers can’t correctly distinguish the difference between industrial compost and domestic compost, resulting in a large number of bags that need industrial composting being mistakenly put into domestic compost.

Try a variety of technological innovations.

In product design, we developed an intelligent identification system to help sorting equipment accurately identify different types of biodegradable bags through special color identification. This system has been put into use in pilot cities, and the sorting accuracy has increased from 65% to 92%.

In the aspect of formula optimization, we developed a new degradation promoter, which improved the decomposition speed of bags at room temperature by 40%. At the same time, the compound strain developed by us in cooperation with Agricultural University can shorten the composting cycle from the traditional 180 days to 120 days, greatly improving the treatment efficiency.

We have also established a complete product traceability system. Each batch of products has an independent traceability code. Consumers can know the source of

, production technology and the latest recycling point information of the bag by scanning the QR code on the package. At present, this system has covered more than 200 cities in China.

Consumer Guide: Proper use is very important.

Recognize the logo: industrial compost bags need professional treatment, and domestic compost bags can be degraded in the backyard. Please pay attention to the certification mark and instructions on the bag.

Reuse: It is recommended to use each bag more than 10 times. Please keep it properly after use to avoid direct sunlight and high temperature environment.

Correct delivery: confirm that there are composting facilities in the local area before choosing to use them. You can check the nearest recycling point through our official website.

Proper storage: avoid high temperature exposure and prevent premature degradation. It is recommended to store in a cool and dry place, and the temperature should not exceed 35℃.

Future plans

We believe that with the progress of technology and the improvement of supporting facilities, biodegradable bags will play their due environmental protection value. At present, the products we are developing can reach 80% degradation rate within 6 months, and almost no microplastics is produced. This technology is expected to be put into mass production in 2025.

Every environmental protection choice needs the joint support of technology, facilities and public awareness. Let’s work with many partners to promote the green development of the entire industrial chain.

(The data in this paper comes from laboratory test records and market research reports.)