2024 is a watershed for the agricultural plastic film industry. In the demonstration park of Shouguang Vegetable Base in Shandong Province, the technical director, showed us the use effects of different plastic films: “These new biodegradable films have been used for more than half a year, and now they are basically out of sight. And the traditional PE mulch film next to it, even after a complete growing season, still has a lot of residue in the soil. “

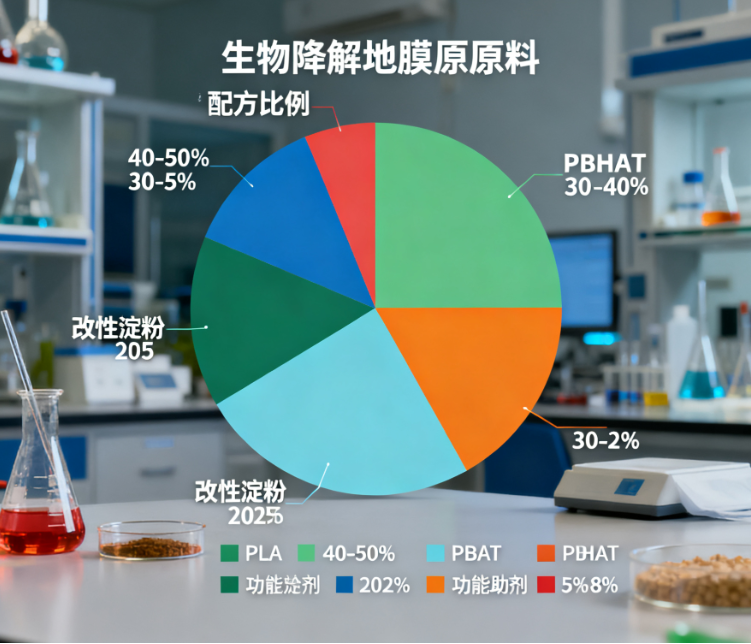

a major technological breakthrough has been achieved in the biodegradable mulch film with PLA (polylactic acid) and PBAT (poly adipic acid/butylene terephthalate) as the main raw materials.

Specific technical parameters display:

The PLA content is controlled at 40%-50% to ensure the rigidity of plastic film.

PBAT content is 30%-40%, which ensures the toughness of plastic film.

The addition of modified starch is 20%-25%, which promotes the degradation process.

5%-8% of functional assistant, which improves the use performance.

Regional customization of material formula

According to the agricultural needs of different regions, enterprises have developed a series of formulas:

Formula in Northeast China: The proportion of PLA increased to 55%, enhancing low temperature resistance.

Formula in Northwest China: PBAT content is adjusted to 45% to improve wind resistance.

Formula in South China: Increase starch content to 30% to accelerate degradation in hot and humid environment.Regional customization of material formula

Significant changes in technical indicators under the new regulations

- The degradation cycle is more scientific and strict.

According to the latest Technical Specification for the Application of Biodegradable Plastic Film issued by the Ministry of Agriculture and Rural Affairs:

The degradation rate of industrial composting environment is required to increase from 85% to 92%.

The test period of soil environmental degradation was extended from 18 months to 24 months.

Accelerated degradation test in newly added high temperature and high humidity environment

It is required to verify the degradation performance in different soil types

- The ecological security requirements have been comprehensively improved.

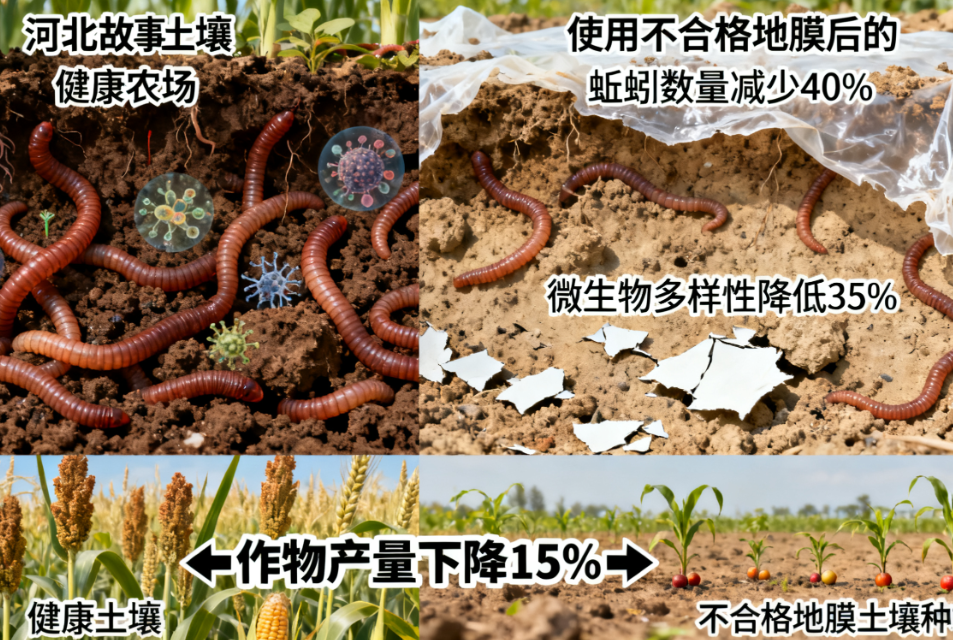

Last year, a case of soil ecological damage caused by the use of unqualified plastic film in a farm in Hebei attracted the attention of the industry. The test report shows that:

The number of earthworms in the soil decreased by 40%

Microbial community diversity decreased by 35%

Crop yield is reduced by 15% in this season.

To this end, the new regulations have particularly strengthened the ecological indicators:

The survival rate of earthworm in 14-day acute toxicity test is ≥95%.

The decline of soil microbial diversity index shall not exceed 10%

The limit of heavy metal content is tightened by 50% compared with the old standard.

Detection of new phthalate esters

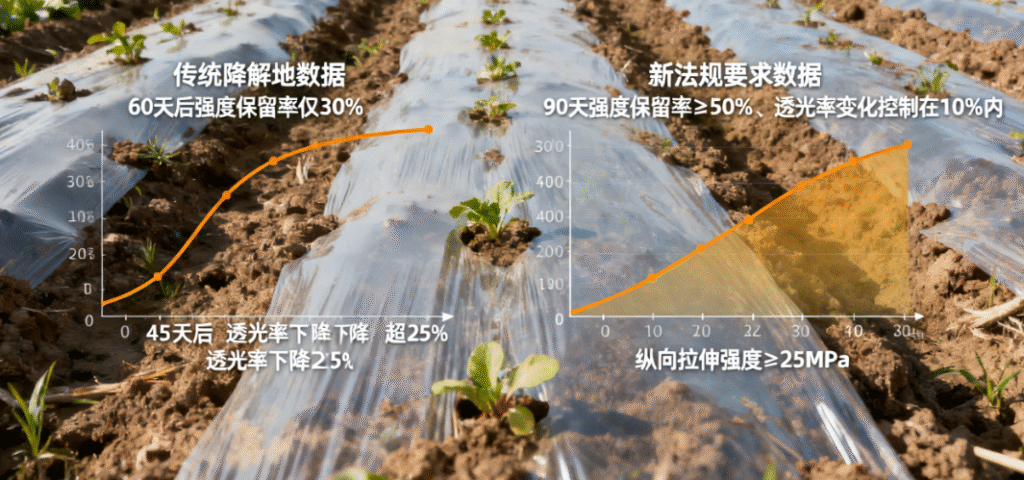

- More precise mechanical performance requirements.

In the field test of Xinjiang Corps for two years, it was found that:

The strength retention rate of traditional degradable plastic film is only 30% after 60 days of use.

The light transmittance decreased by more than 25% after 45 days of use.

The thermal insulation performance is obviously attenuated at low temperature.

The new regulations make targeted requirements for this:

After 90 days of use, the strength retention rate is ≥50%.

The change range of light transmittance is controlled within 10%

Insulation performance attenuation shall not exceed 15%

Longitudinal tensile strength ≥25MPa

Depth analysis of regional adaptability

Through continuous monitoring of major agricultural areas in China, we found that:

Characteristics of Northeast China:

The effective use period is 120-150 days.

The required thickness is above 0.012mm

The degradation start time is controlled at 120 days after use.

Low temperature resistance is required.

Practice in Northwest China:

The stationmaster of an agricultural technology extension station in a county of Gansu introduced: “We have strong wind and sunshine here, and the plastic film should give consideration to both windproof and moisture conservation. Through comparative tests, the film with a thickness of 0.010mm and anti-ultraviolet agent is the best. “

Demand in South China:

The effective use period is 60-90 days.

The thickness of 0.008mm is suitable.

Require rapid degradation start-up

It is necessary to prevent premature degradation in high temperature and high humidity environment

Deep analysis of systematic solutions

New idea of formula optimization

The plastic film developed by us in cooperation with the Academy of Agricultural Sciences adopts an innovative five-element system:

PLA provides the basic skeleton structure.

PBAT ensures flexibility

Modified starch promotes degradation (25%)

Nano-calcium carbonate enhances mechanical properties

Functional additives improve weather resistance.

Fine adjustment of production process

Production records of plastic film factory show the effect of process optimization;

The extrusion temperature decreased from 170℃ to 150℃, and the tensile strength increased by 20%.

The die temperature is controlled at 145 5℃, and the product uniformity is improved.

The traction speed is reduced by 15%, and the thickness deviation is controlled within 0.001 mm.

When the temperature of cooling water is raised to 25℃, the internal stress is reduced by 30%.

Guide to key points of use

Selection suggestion

Selecting degradation cycle according to crop growth period

Select the thickness according to the local climate conditions.

Select formula with reference to soil type.

Use skills

Keep close to the ground when laying.

The edge pressure soil should be firm.

Pay attention to the weather conditions when laying.

matters need attention

Avoid working in extreme weather.

Pay attention to storage conditions to prevent premature degradation.

Do a small area test before use.

Industry trends

Policy support has increased.

Recently, the Ministry of Agriculture and Rural Affairs issued a series of policies:

Incorporate biodegradable plastic film into the scope of agricultural machinery purchase subsidy

Establish a demonstration base and give financial support.

Strengthen the supervision of plastic film pollution control

Technological progress continues to accelerate.

Expert advice

Suggestions of agricultural technology extension experts:

“The promotion of biodegradable plastic film should be divided into three steps: first, experiment and demonstration, so that farmers can see the effect; Secondly, technical training, teaching the correct use of methods; Finally, the whole service is to solve the problems in use. “

Future prospects

With the continuous maturity of technology and the continuous decline of cost, biodegradable plastic film is welcoming a period of rapid development. It is estimated that by 2025, the usage of biodegradable plastic film in China will reach 500,000 tons, which can reduce the residual pollution of PE plastic film by 2 million tons.

Data source:

Agriculture rural bu agriculture ecology Yu resources protection main station

China Academy of Agricultural Sciences Institute of Soil Fertilizer

National Strategic Alliance for Technological Innovation of Biodegradable Materials Industry

Field survey data