In the company’s sample room, the business manager is carefully checking the biodegradable bag samples to be sent to the United States. “This is a custom-made shopping bag with a thickness of 15 μm. We need to ensure that each sample meets the BPI certification standard.” This kind of work scene truly reflects our current development situation-relying on excellent product quality, we will gradually open up European and American markets.

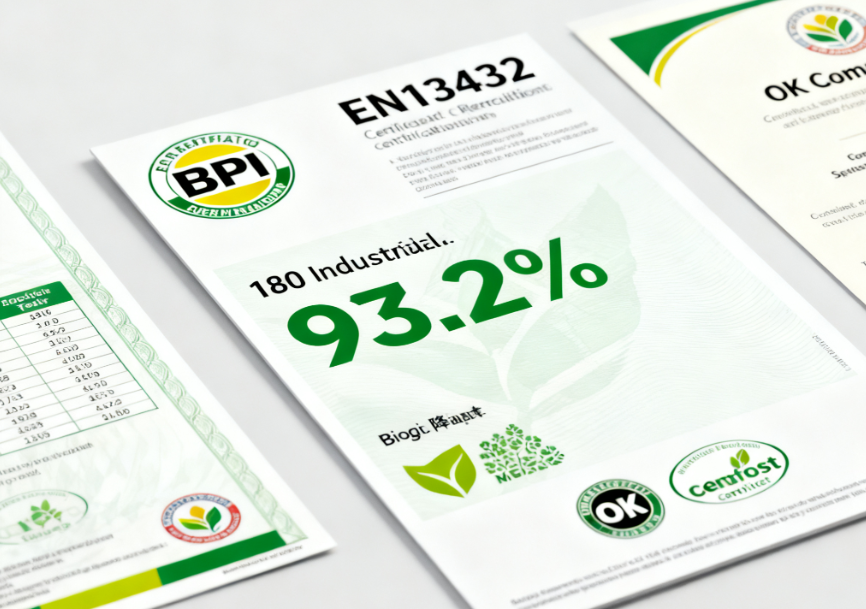

As a biodegradable packaging manufacturer that has passed the triple certification of BPI, EN13432 and OK Compost, we always adhere to product quality as the core and win the trust and cooperation of overseas customers through real product performance.

Focus on product quality and lay a solid foundation for development.

In the production process, we always adhere to strict quality standards:

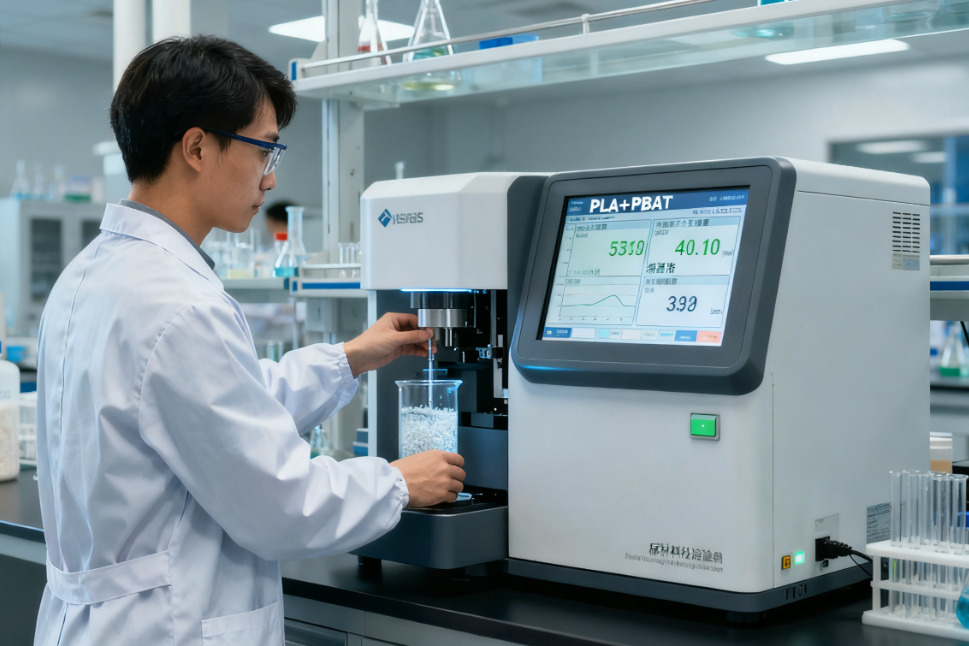

Every batch of PLA+PBAT raw materials must go through a strict testing process before being put into storage. The raw material inspection laboratory established by us can accurately detect the key indexes such as molecular weight and melting index of raw materials to ensure the stable and reliable quality of raw materials. “Although our scale is not the largest, we never compromise on quality control.” The head of the quality department said.

In the production process, we implement the whole process of quality control. From feeding, extrusion to molding and cutting, each link has clear operating specifications and inspection standards. In addition, we implement a full inspection system for finished products to ensure that each ex-factory product meets customer requirements.

Certification qualification: a passport to open the international market

We know that product certification is essential to enter the European and American markets:

In the process of applying for BPI certification, we invested a lot of time to improve the quality management system and finally passed the certification with excellent test results. Certification data show that the biodegradation rate of our products reaches 93.2% in 180 days under industrial composting conditions, far exceeding the standard requirement of 90%.

The passing of EN13432 certification proves that our products fully meet the environmental protection requirements of the EU market. In the ecotoxicity test, the biomass of plants cultivated with the degradation products of our products is 5.8% higher than that of the control group, showing excellent environmental friendliness.

Keep innovating and look to the future.

In research and development, we have maintained continuous investment:

The PLA modification project currently under way has achieved initial results. By adding natural toughening agent, the new formula can still maintain good flexibility at the low temperature of MINUS 20℃. “This breakthrough enables us to explore the Nordic market.” The R&D engineer said excitedly.

At the same time, we are also optimizing existing products. By adjusting the starch content and particle size distribution, the tensile strength of the product was improved by 20% on the premise of ensuring the degradation performance. These seemingly minor improvements are accumulating into our core competitiveness little by little.

Quality service, win trust

In customer service, we always adhere to the “honesty-oriented”:

Every new customer will receive a sample set sent by us, including products with different thicknesses and specifications, which is convenient for customers to test and verify. We also provide detailed technical materials to help customers better understand the product features.

It is this persistence in quality and honesty to customers that enables us to gain a firm foothold in the fierce international market. From the initial sporadic orders to the current stable monthly export volume, we have proved by practice that as long as the products are excellent, we will certainly win the market.

Looking forward to the future, we will continue to uphold the concept of “quality first” and grow together with global customers with better products and services. We believe that doing every detail in a down-to-earth manner will eventually yield more room for development.