In the tide of global environmental awareness awakening, biodegradable packaging materials are becoming the key solution to solve the plastic pollution problem. As an enterprise deeply involved in the field of environmental protection packaging, we are always committed to providing biodegradable packaging solutions that meet international standards for the global market through continuous technological innovation and strict quality control.

Fine management of raw material system

In the construction of raw material supply chain, we have established a multi-dimensional quality control system. All PLA raw materials are processed from non-grain aged corn. By optimizing the fermentation process, the starch conversion rate reaches over 92%. PBAT raw materials adopt new catalytic synthesis technology, which not only ensures the biodegradability, but also significantly improves the mechanical properties of the materials.

We have established a raw material traceability system, and each batch of raw materials has an independent traceability code to record the whole process data from production to transportation. At the same time, we have established a joint laboratory with raw material suppliers to jointly develop new modified materials and continuously improve the performance of raw materials. The toughening modification project of PLA completed last year increased the elongation at break of raw materials by 40% and effectively improved the service performance of products.

The intelligence of manufacturing is further upgraded.

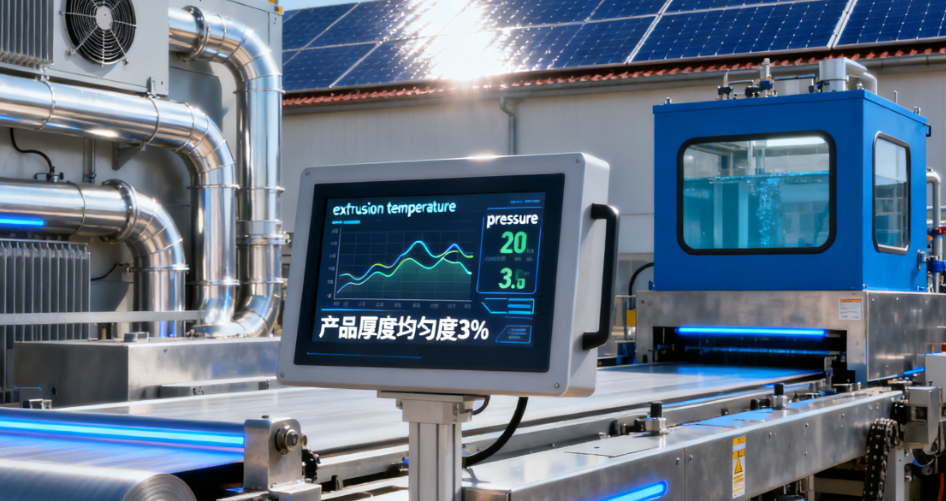

In the production process, we continue to promote intelligent transformation. The imported German automatic production line is equipped with an online monitoring system, which can monitor the key parameters such as extrusion temperature and pressure in real time to ensure the process stability. By optimizing the die runner design, the product thickness uniformity is controlled within 3%, reaching the leading level in the industry.

And the environmental protection performance of the production process. Through the waste heat recovery system, the energy consumption of the production line is reduced by 25%; The installed wastewater treatment device realizes the recycling rate of water resources above 95%; The solar power supply system can reduce carbon emissions by about 200 tons per year. These measures not only reduce the production cost, but also practice the concept of green manufacturing.

Meet international standards in quality certification.

In product certification, we control the quality by exceeding the standard. In the process of BPI certification, our products performed well in the biodegradability test, not only meeting the standard requirements, but also the degradation stability under different temperature and humidity conditions was highly evaluated by the certification body.

The passing of EN13432 certification proves the environmental safety of the product. We have established a perfect ecotoxicity testing system, in addition to the testing items required by the standard, we have also added the impact assessment of soil microbial diversity. The test results show that the microbial community richness of the soil using the degradation products of our products is 15% higher than that of the control group, which shows a positive impact on soil ecology.

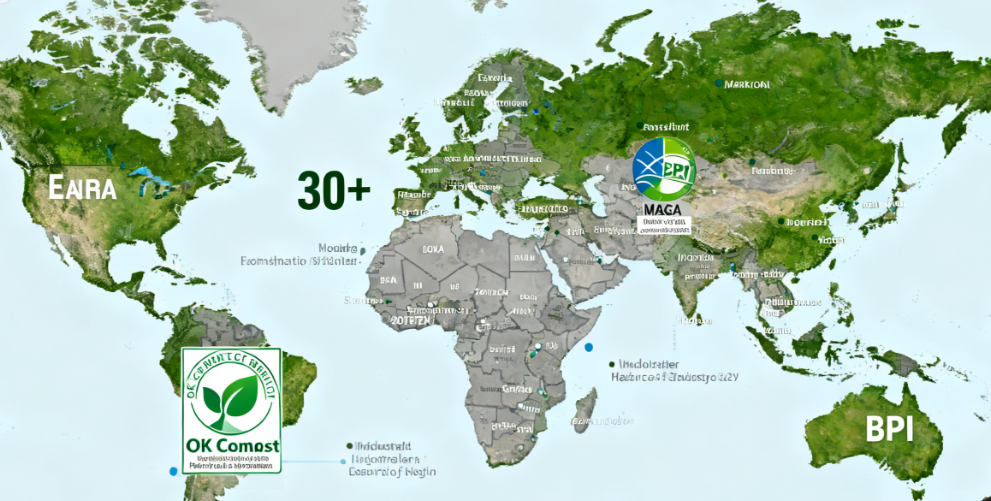

Precise development of global market

With excellent product performance, our market network has covered more than 30 countries and regions around the world. In view of the strict requirements of environmental protection in the European market, we have developed a series of products that have passed the OK Compost household composting certification; For the North American market, a series of industrial compost products conforming to BPI certification were introduced.

We have established a professional customer service team to provide full-process services from product selection to use guidance. At the same time, we have opened a 24-hour service hotline to solve the problems encountered by customers in the process of use in time.

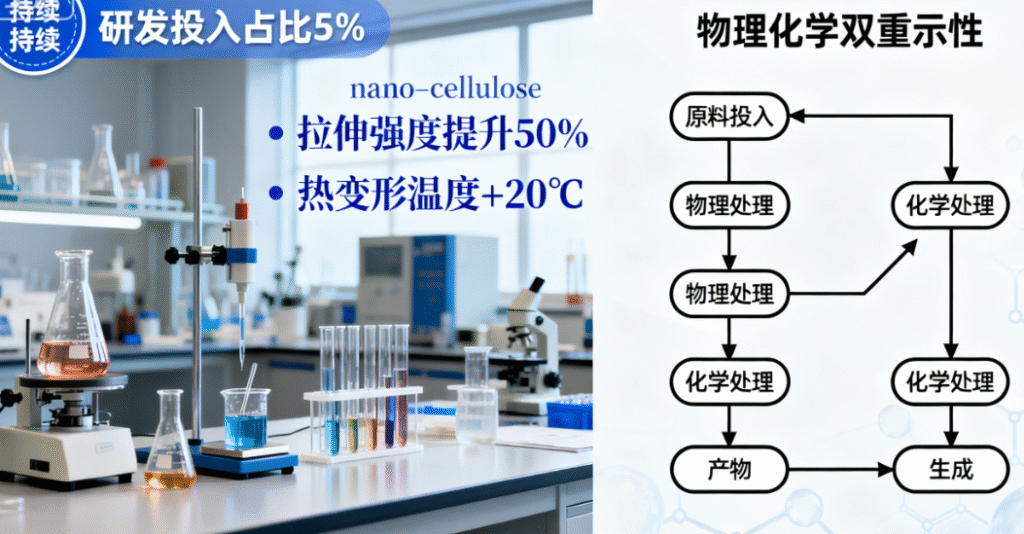

Continuous investment in product technology research and development

R&D innovation is the core driving force of enterprise development. We invest 5% of our sales revenue in R&D every year and establish a perfect R&D system. At present, the nano-cellulose reinforcement project is being promoted. By adding nano-cellulose into PLA matrix, the tensile strength of the material is increased by 50% and the thermal deformation temperature is increased by 20℃.

In the recent starch modification project, the compatibility between starch and PLA was significantly improved by physical and chemical double modification technology, which laid the foundation for developing biodegradable materials with high starch content.

Systematic quality management

We have established a quality management system covering the whole process. From the time the raw materials are put into storage, each batch of materials must go through strict testing procedures; In the production process, there are 36 quality control points to implement the whole process of quality monitoring; Before leaving the factory, the finished product must pass 12 tests including physical properties and degradation performance.

We introduced advanced laboratory information management system to realize real-time collection and analysis of test data. Through big data analysis, we can find the trend of quality fluctuation in time and implement preventive control. The application of this system keeps the qualified rate of our products above 95%.

Conscientiously practice environmental responsibility

As a manufacturer of environmental protection materials, we always integrate the concept of sustainable development into all aspects of enterprise operation. Through process optimization, the energy consumption per unit product is 30% lower than the industry average; Through the circulating water system, 100,000 tons of water is saved every year; Through the construction of green logistics system, the carbon emissions of transportation links are reduced by 20%.

We also actively participate in the formulation of industry standards and promote the establishment of a more perfect evaluation system for biodegradable materials.

Strategic layout of future development

In the future, we will continue to deepen the technical accumulation in the field of biodegradable packaging. It is planned to build a new research and development center in the next three years, focusing on breaking through the performance bottleneck of bio-based materials; At the same time, the production base will be expanded, and the production capacity is expected to increase by 50% after production.

We believe that with the continuous progress of technology and the continuous improvement of environmental awareness, biodegradable packaging will surely usher in a broader development space. Let’s work together to contribute to the environmental protection of the earth.